Rapid prototyping has revolutionized the landscape of product development, offering a dynamic and efficient approach to bring ideas from concept to reality. At its core, rapid prototyping is a process that utilizes advanced technologies such as 3D printing to quickly and cost-effectively create physical models of designs. These prototypes serve as tangible representations that enable designers and engineers to test and refine their concepts in a much shorter timeframe than traditional methods would allow. The versatility of rapid prototyping extends to various industries, from automotive and aerospace to healthcare and consumer electronics.

One of the key features of rapid prototyping is its ability to accelerate innovation cycles. Traditional manufacturing processes often involve lengthy lead times and significant tooling costs, but rapid prototyping bypasses these constraints. Instead, intricate designs can be translated into physical prototypes within hours or days, enabling rapid iterations and quick adjustments based on real-world testing. This iterative nature not only speeds up the development process but also fosters a culture of experimentation and continuous improvement.

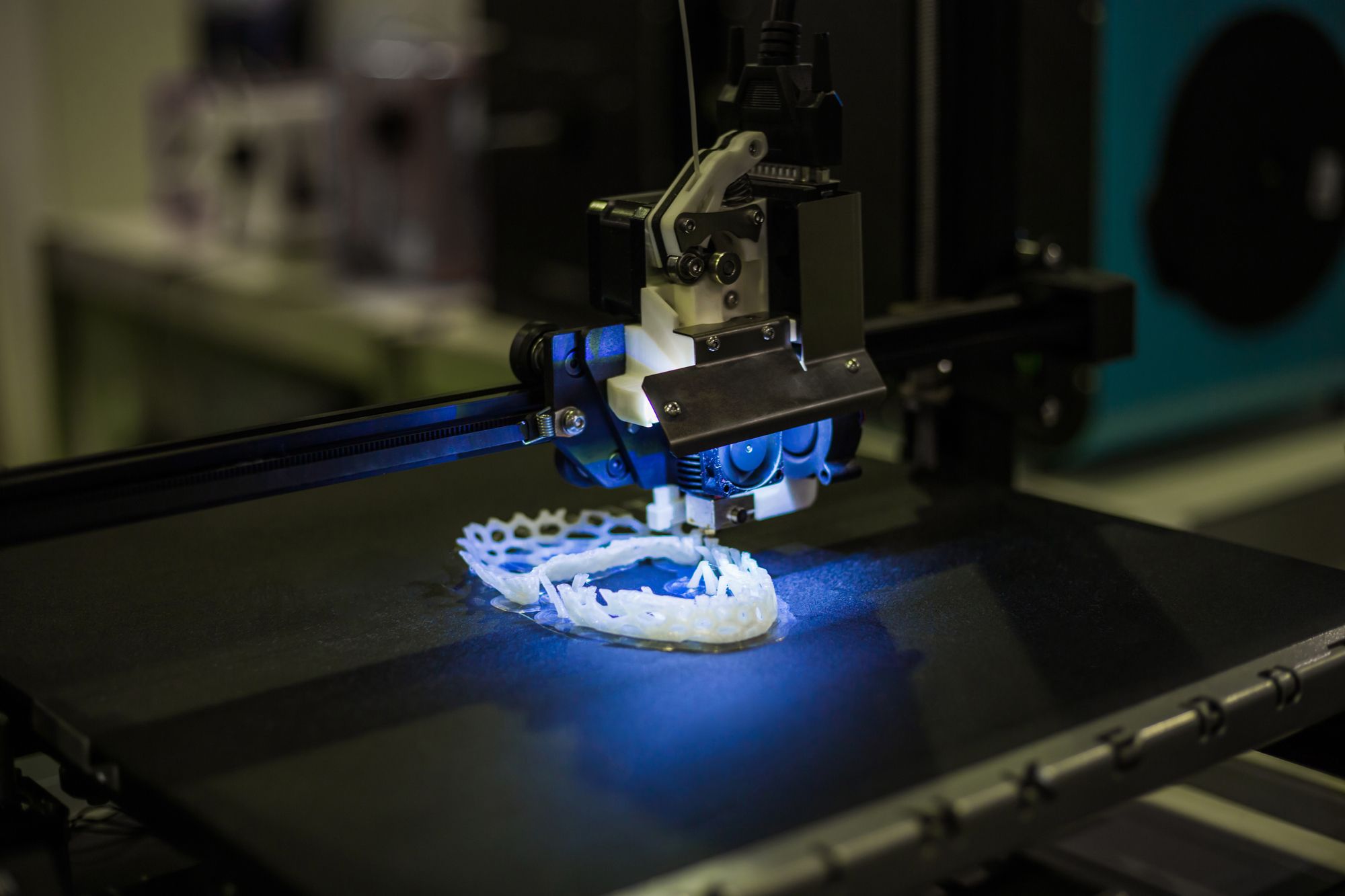

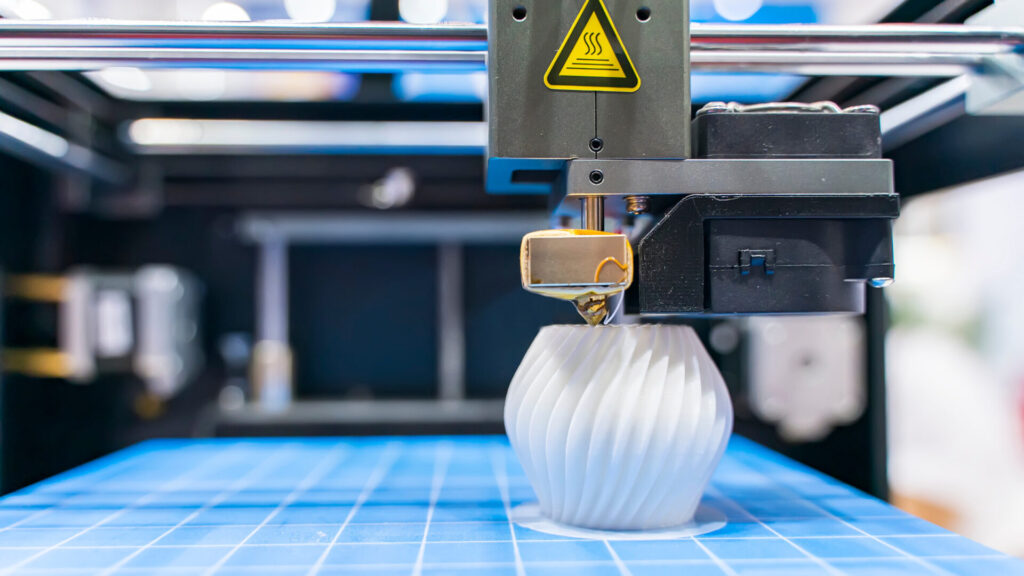

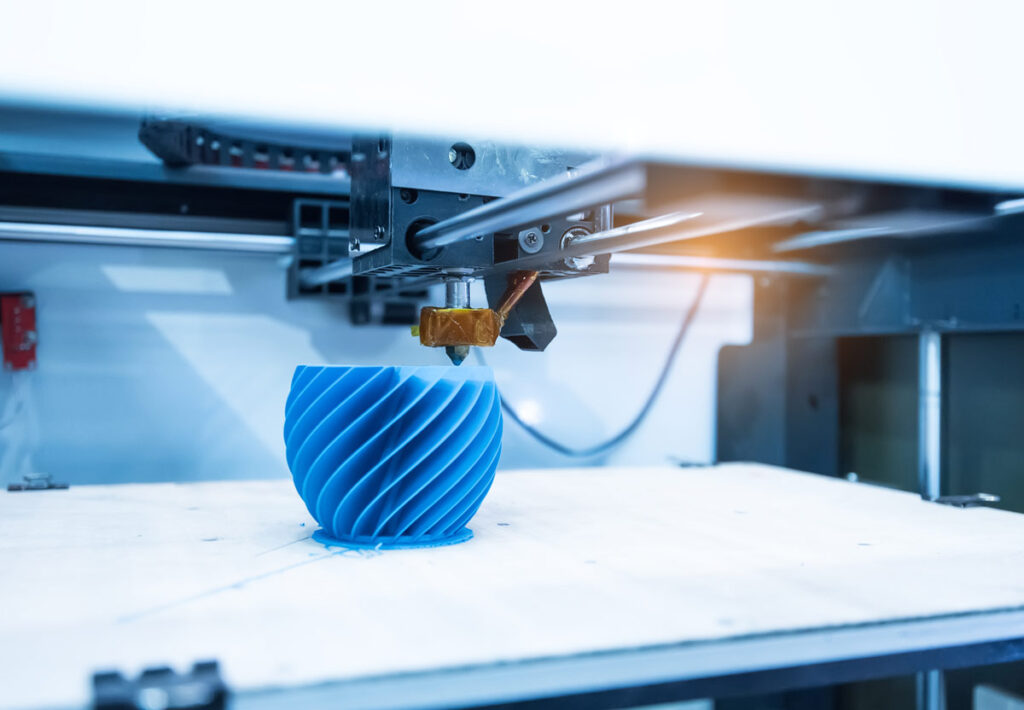

The visual impact of rapid prototyping is compelling. High-quality photos of the prototyping process capture the precision of layer-by-layer construction, showcasing the transformative journey from digital models to tangible prototypes. These images often reveal the diversity of materials employed, highlighting the adaptability of rapid prototyping to various project requirements. In essence, rapid prototyping is not just a technological advancement; it’s a paradigm shift that empowers innovators to turn ideas into functional prototypes swiftly, providing a tangible bridge between imagination and realization.